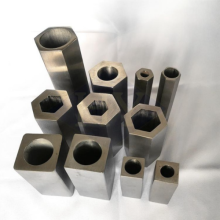

Brass Precision Auto Turned Parts

| Payment Type: | L/C,T/T,Western Union |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Bag/Bags |

| Delivery Time: | 10 Days |

| Packaging: | Interior: Blisters Exterior: Carton |

|---|---|

| Productivity: | 200000 pieces / month |

| Brand: | HYC OR OEM |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | Guangdong, China |

| Supply Ability: | 200000 pieces / month |

| Certificate: | ISO9000 |

| HS Code: | 7616999000 |

| Port: | Guangzhou,Shenzhen |

Click on the follow link to find out more information: https://www.hycmetal.com/precision-brass-parts/

Company Info

- Company Name: Huaying Chuang Precision Machinery Co., Ltd.

- Product/Service: CNC Turning parts , CNC Machining Parts , Gear Cutting , Lighting Accessories , Precision grinding parts , Hardware Parts

- Capital (Million US $): 500.000RMB

- Year Established: 2016

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 81% - 90%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: 7

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): Below 1,000 square meters

- Factory Location: dongguan city, guangdong province, China

- Contact Person: Mr. Zou

- Tel: 86--15013568605

Premium Related Products

Other Products

Hot Products

strong magnetic tube filter frame separatorMagnetic Rubber holdersNeodymium Cylinder MagnetPowerful Permanent Neodymium Arc MagnetPowerful Permanent Neodymium Countersunk MagnetPowerful Permanent Neodymium Block MagnetPowerful Permanent Neodymium Holding and Retrieving MagnetsHeavy Duty Holding And Retrieving MagnetsOffice Magnetic Red PushPinsMagnetic Color Name BadgesMagnetic Rotors for Permanent Magnet MotorsMagnetic Couplings For Magnetic Drive PumpMagnetic ball jointsLarge Ring Rare Earth Permanent MagnetStrong NdFeB Magnetic couplingHigh-Speed Magnetic Rotor for Motor Parts